Frequently Asked Questions

Frequently Asked Questions about the Greenix Panel System and Structural Insulated Panels (SIPs)

No, GX Panels are structural panels, but they can also also be used as a cladding panel.

Yes, the GX Panel is a structural wall. Standalone up to 14 feet and up to three stories as a system.

Yes and no. Most panel installations are completed by licensed general contractors.

Typical delivery times range between 6 and 12 weeks.

No. There is no wood or wood components in the GX Panel. The building system is manufactured using galvanized 26 Gauge Embossed Steel and integrated structural members for attaching siding or other materials.

Building with Greenix Panels has many sip design advantages for you, your architect and your builder:

Design Flexibility

Greenix Polyurethane Panels create new possibilities of design without the constraints of conventional building materials.

Additional Floor Area

Greenix Polyurethane Panels create additional warm living space in the roof by eliminating conventional trusses. This can provide an additional 25% of floor space at no additional cost and makes use of all of the potential space in the building.

Thermal Performance

Greenix Polyurethane Panels can offer a thinner wall thickness than a conventional wall, but still deliver improved insulation values, gaining greater internal space for the same size overall footprint. Unbeatable insulation value means energy costs can be reduced by up to 60% over traditional construction.

Structural Advantages

Structural superiority has been proven by independent testing. Point loads can be dispersed through the monolithic structure.

Construction Benefits

Greenix Panels are better for your builder. Pre-cut and fabricated panels reduce installation time by 60%. The building process requires less skilled labor and less supervision. Specialized tools are not required and fixed pricing allows budgets to remain accurate.

The composite structure of Greenix Panels offer many physical advantages:

Strong

Once completed, a Greenix Panel structure forms a monolithic shell is up to seven times stronger than a traditional frame structure and is a popular building method in areas subject to earthquakes, tornadoes and hurricanes. This provides a building with a very robust and solid feel which can be indistinguishable from a traditionally constructed building once complete.

Airtight and Quiet

Buildings constructed with Greenix Panels are quieter and more comfortable to live in. The panels provide significant resistance to airborne sound. The inherent airtight construction lends itself to modern ventilation systems which reduce energy costs and improve air quality.

Resistant to Rodents, Mold and Microbes

The insulating foam core and the OSB facings used in the manufacture of Greenix Panels do not provide any food value to vermin and are resistant to attack by mold and microbes.

Integral Insulation

The solid core of foam insulation in the panels cannot slump over time and the minimal thermal bridging ensures that the building is heated evenly, free from cold spots and condensation. The building will benefit from reduced heating costs for its entire lifetime. This is an important consideration at a time of spiraling energy costs.

Rigid Surface for Installations

The standard OSB skin of a SIPs structure provides a continuous surface for easy installing of services, lights, hangings and kitchen units without having to build in additional support in the structure.

Choice of Finish

A Greenix Panel structure will form the hidden shell of the building. The external walls can then be finished in many ways. These can include traditional cavity and facing brickwork, stucco and siding. Internal walls are normally finished with drywall. Roofs are finished as normal, although the inherent strength of a Greenix Panel roof does not require the same weight of finish as a conventional vented roof void. This can allow the use of a lightweight roof finish if desired. Although an alternate roof design may be required.

Cost comparisons have shown that building with Greenix Panels is no more expensive than traditional building techniques when the following factors are taken into consideration:

Reduced Cost of Land

A Greenix Panel SIP Plan can be designed to utilize attic space, thus creating additional living area which results in a smaller footprint. Example: A three bedroom house can be turned into a five bedroom house on the same size lot.

Reduced Cost of Foundation

A Greenix Panel structure created a lighter building envelope than brick or block and therefore could allow for a reduced foundation design.

Reduced Cost of Loss through Damage or Theft

The elements which make up a SIPs structure are generally very large and robust and are therefore inherently unlikely to be damaged or stolen from the jobsite. A significant percentage of traditional building materials are either lost, damaged or stolen from jobsites. The speed of build and the nature of Greenix Panels virtually eliminates this problem.

Reduced Cost of Labor

A Greenix Panel structure simplifies the process of construction and can reduce construction time by up to 60%. Once the foundations have been completed, a Greenix Panels pre-engineered structure arrives at the jobsite and within weeks can become a weather-tight structural shell ready for windows, doors, services and internal and external finishes. The nature of Greenix Panels provides a completed unit that also reduces installation steps and so reduces the eventual cost of multiple inspections.

Reduced Cost of Waste Disposal

A Greenix Panel structure is pre-engineered off-site to avoid both the additional labor and the ever increasing cost of the safe disposal of waste materials.

Reduced Jobsite Costs

A faster build program will reduce the overall cost of project management, and in turn will also reduce the cost of hiring scaffolding, plant, safety and security equipment and temporary accommodations.

Reduced Heating Costs

The unbeatable insulating qualities of Greenix Panels allow a much smaller heating system, with combined with a mechanical ventilation system to be installed. This will permanently reduce heating bills by up to 60% over the lifetime of the building when compared with traditional methods of construction.

Quicker Return on Investment

Building a Greenix Panel structure can radically increase the speed of construction, providing a quicker return on investment. This allows the capital to be used on the next project when it would otherwise still be tied up on a traditional build. A significant gain can be made over a period of time maximizing the return on the initial investment and maintaining a positive cash flow.

Better Resale Value

Greenix Panel houses are attractive to future buyers and occupants, due to the reduced utility costs and the many other benefits that a Greenix Panel building provides.

Environmentally Friendly Materials

The standard outer skins of GP/W Greenix Panels are manufactured using Oriented Strand Board (OSB). This is made from young fast growing trees which are deliberately grown in plantations accredited by the Forest Stewardship Council (FSC). Young trees produce oxygen and remove more carbon dioxide from our atmosphere than mature trees and are renewable, recyclable, bio-degradable and non-toxic. The core insulation is Polyurethane foam (PUR) which is CFC and HCFC free and has an ozone depletion potential of zero.

Reduced Timber Usage

To make a product with the same strength, timber uses 20% of the energy needed to make concrete. Timber is naturally low in thermal conductivity and an excellent insulator. It is 15 times better as an insulator than concrete and 1770 times better than aluminum. A 1″ timber board has better thermal resistance than a 5″ brick wall. When compared with traditional timber frame buildings, Greenix Panel construction uses approximately 50% less wood, which all adds to the positive environmental impact of this form of construction.

High Insulation Value

Greenix Panels provide an extremely high thermal performance and R-values can be as high as R-40. There is minimal thermal bridging compared to conventional construction and the insulation will not sag or slump over time. The SIP envelope is designed to be draft free and is warm in the winter and cool in the summer. This drastically reduces energy consumption which leads to a corresponding reduction of up to 60% in carbon dioxide emissions from the burning of fossil fuels for the lifetime of the building.

Minimal Waste

Building with Greenix Panels produces less waste than other forms of construction. The panels are engineered in a controlled environment, reducing the amount of waste produced on the building site and allowing unused materials to be recycled.

Green Building Programs

Building with Greenix Panels substantially cut home energy consumption, making it easy to reach Energy Star qualifications. Greenix Panels contribute towards certification under both the LEED and NAHB standards. An Energy Star labeled home qualifies for LEED credits in multiple categories.

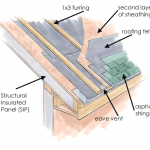

For asphalt shingles, a cold roof works best.

Create a cold roof by applying a layer of sheathing over 1×3 furring 16 in. on center. Venting at the ridge and eave allows air to move freely between the two layers of sheathing. This style of roof helps to prevent moisture buildup.

If you would like to receive a price quote on a project, please Request a Quote

When evaluating the cost of building with the Greenix Panel System, you need to look at the overall construction costs and long-term operating costs, not just the cost of the material. Using Greenix Panels result in less waste, less field labor requirements (along with the associated field labor overhead costs, such as transportation, lodging, meals, benefits, etc.), much faster construction time (and fewer weather delays), lower HVAC equipment costs, and greater comfort. Long-term operating costs for utilities are greatly reduced. Greenix Panels are even more competitive when the design is optimized to incorporate them. Consequently, architects design dimensions at two-foot and four-foot increments, engineer roof pitches at steeper angles to increase loft square footage, and make other similar adjustments to take full advantage of Greenix Panel capabilities. Using the Greenix Panel System, therefore, usually results in lower overall building costs and better value.

Yes. Greenix Panel structures require considerably less framing lumber than a conventionally framed building. This saves trees. OSB is made from the 37% of a tree that is normally waste from making solid lumber. Solid lumber, as used in typical wood-frame homes, requires 63% of the wood from harvested trees. Greenix Panels are pre-cut in the factory, result in far less “job-site waste.” The small amount of wood scraps resulting from the Panel manufacturing process at the manufacturing facility is used for other products or recycled, rather than going into landfills.

We use a low-pressure foaming system designed to maximize the advantages of the foam properties. The cured foam is inert and non-hazardous. The foam process used in Greenix Panels uses no “ozone depleting substances”, such as chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), hydrobromofluorocarbons (HBFCs), halon, methyl bromide, carbon tetrachloride, or methyl chloroform. Only EPA-approved materials are used in the manufacture of Greenix Panels. Greenix Panels polyurethane foam contains no formaldehyde. We also offer foam that contains agricultural-based oils derived from soy beans, corn, sugar beets, and/or sugar cane. The foaming equipment is cleaned with hot water and a detergent, and the small amount of residue is safely disposable.

No more than in conventional construction. In climates where either termites or ants can cause problems, panel manufacturers recommend that all homeowners use the same preventive treatments (topical sprays around foundations, termite shields, etc.) that they would use in a stick-framed home. Note, however, that the foam within the panels does not provide food value for insects.

Fire requires three components: ignition, oxygen, and fuel. Greenix Panels have no “air” within the solid core of the insulation. The fire cannot “run up the wall” cavity, as is the case with traditional stud construction. Polyurethane foam does not melt. The Greenix Panel system has passed every standard fire test that is required of wood-based or “Type V” construction. To the surprise of some building researchers, data from extensive laboratory fire testing as well as reports from actual house fires indicates that Greenix Panel made structures tend to be more resistant to house fires than standard stud structures.

We test our panels to the American Society for Testing and Materials (ASTM) E84-04 “Standard Test Method for Surface Burning Characteristics of Building Materials” for smoke spread and flame spread. Greenix Panels have a Class 1 foam core. The foam components are formulated to have a flame spread of less than 25 units and smoke spread of less than 400 units.

Doors and windows are identified in the building plan. As part of the manufacturing process, door and window openings are framed and blocked out. When foam is injected into the panel, the door and window frames become an integral part of the panels.

Plumbing is not usually placed in exterior walls, but rather through the floor into the bottom of cabinets. Where exterior wall vent-pipes are necessary, chases can be formed in the foam cores. Island or loop vents are also common practices and can be found in the plumbing codes.

Wiring a Greenix Panel building takes a little extra planning prior to construction. Greenix Panels are designed with a conduit chase and electrical boxes in the foam according to the structure’s plan and “blueprints.” Then, an electrician simply “fishes” the wire through the conduits to where the wire is needed. Wiring chases and boxes can be provided for electrical outlets and switches, wiring junctions, cable television outlets, telephone outlets, computer circuits, etc.

No. Research indicates that the best way to provide a building (such as a home or office) with good indoor air quality requires two essential steps.

1.) The building has to be built as tightly as practical; it is easier to control air movements in a tight structure than in a leaky one.

2.) The building must have modern, upgraded mechanical ventilation features in the HVAC system so that it provides an appropriate and steady flow of fresh air. These modern HVAC features also contribute to cleaner air and better energy-efficiency.

Yes. Four key factors make the average Greenix Panel building very energy-efficient.

1.) Polyurethane foam provides higher insulating value per inch than traditional fiberglass or cellulose insulation.

2.) There is much less wood framing within the typical panel, which increases total R-value.

3.) The foam is continuous and is not susceptible to the commonplace flaws found in average batt installations.

4.) Foam, when bonded directly to the exterior and interior wall “skins,” doesn’t allow air infiltration around it.

Greenix Panel System-made buildings are vastly more energy-efficient, stronger, quieter, and draft free than older building methods likes stud framing with fiberglass batt insulation. Fiberglass is sometimes used for furnace filters because air moves through so freely. Polyurethane foam consists of billions of tiny cells with solid polyurethane cellular walls. Air cannot flow from cell to cell or between cells. Rigid foam insulation is used as solid component insulation in almost every industry concerned about heat transfer, such as the refrigeration industry, for its inherent efficiency and prevention of air movement. These attributes are built right into the Greenix Panel System. Less air movement or leakage translates into far fewer drafts, fewer penetrations of noise, much lower energy bills, and a significantly more comfortable and controllable indoor environment. You can have a quieter, more comfortable home and office.

Greenix Panels are a structural composite system acting like an I-beam. The skins act like the flanges and the rigid core is similar to the web. In short, the three components work together, rather than against one another. The composite assembly yields stiffness, strength, and predictable responses to loads. Greenix Panels have an integral tongue and groove system for joining panels together that also helps carry the structural load. A structure using the Greenix Panel System resist both compressive forces from above and buckling and warping forces from the sides. We test to the American Society of Testing and Materials (ASTM) E72-04 “Standard Test Methods of Conducting Strength Tests of Panels for Building Construction” for compression, transverse, and racking loads. Depending on the type of structural test being administered, Greenix Panels range between two and seven times stronger than traditional framing.

Not only do test results show the panels are stronger, but real-life natural disasters have proven it. The great Hanshin (Kobe, Japan) and North Ridge earthquakes, Hurricane Andrew, a Colorado tornado, a Portland gas explosion, and an Omaha fire, have done more to prove structural insulated panels’s strength to homeowners, architects, and builders than all the scientific tests.

Greenix Panels save time, money, and energy. They outperform other building methods in virtually every aspect because of the structural strength, ease of erection, and insulation value of the components.

When someone says “R-value”, what they are talking about is resistance to heat flow in a given medium, such as fiberglass insulation. The higher the number, the greater the resistance to flow. Thus, a product with a value of R-25 is much better than a product with a value of R-13.

In reality, this reasoning doesn’t take into account all the other components that go into making a wall: wood or steel studs every 16 or 24 inches reduce the overall R-value, and allow airflow within the wall space. In addition, other construction materials and components, such as bracing, nails or screws, wiring and switch boxes, and any number of things that are not insulation, and, in all likelihood, have low R-values, negatively affect the overall quality of an insulated wall, floor, or ceiling. Poor installation of fiberglass batt insulation can also reduce the R-effect significantly. A wall with fiberglass insulation rated at R-13 can have an actual result of R-10 or less due to these other factors.

Laboratory Testing

A new study by the Oak Ridge National Labs (ORNL) in Tennessee proves that a 4″ Structural Insulated Panel wall outperforms traditional 2″ x 4″ stick and batt construction, and even edges out 2″ x 6″ construction in terms of thermal performance. Structural Insulated Panels (if made with structural “skins” such as OSB) are structural elements. There are no studs or braces to cause breaks in the insulative action. The end result is a more comfortable, energy-efficient building that performs up to specifications in real-world conditions. Unlike stick and batt construction, which can be subjected to poorly installed – even missing – insulation; the nature of the Greenix Panel System is such that the structural and insulative elements are joined and bonded together as one. There are no hidden gaps. A solid layer of foam insulation is integral to panel construction.

The ORNL study found that Structural Insulated Panels perform at approximately 97% of their stated R-value overall, losing only 3% to nail holes, seams, splines and the like. Wiring chases are preformed into the foam core, providing a continuous layer of insulation keeping the elements out and the interior free of drafts and cold spots. Greenix Panels are superior to traditional, old-fashioned methods of building construction.